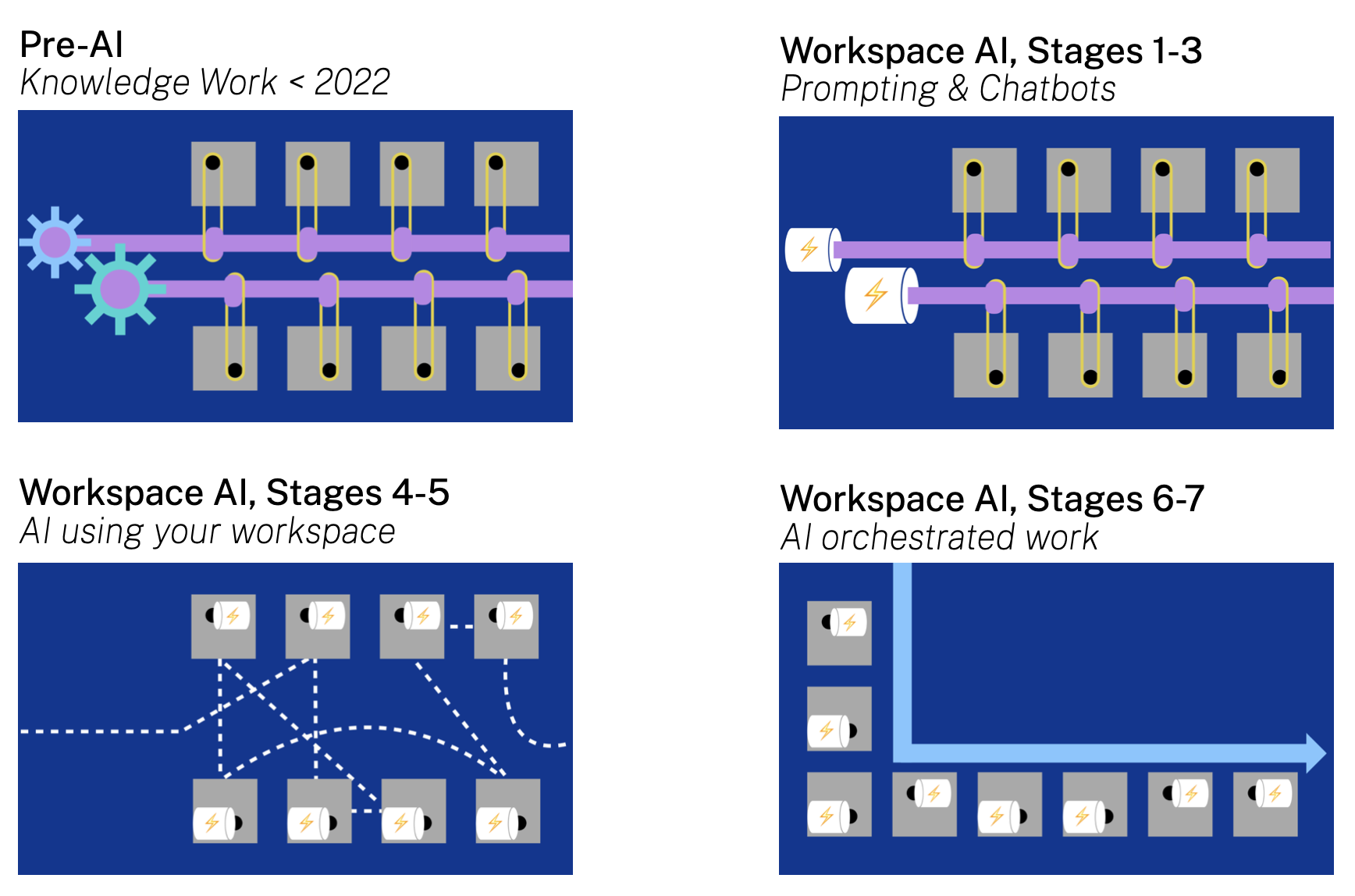

Yes, AI will transform the workplace. But if you’re only looking at its current capabilities and how it’s used today, it’s easy to feel skeptical, as the impact of today’s AI can feel incremental at best and underwhelming at worst. That’s one reason I recently laid out a 7-stage roadmap for how human-AI collaboration will evolve in the workplace. Transformation happens in phases, not all at once. Each stage builds on the one before it, and you can’t skip steps.

But even with a step-by-step roadmap to the future, people still get stuck thinking about AI in the context of automating today’s tasks within today’s organizational structures. If this is you, if you believe the future of work is just us humans doing the same things while AI handles the repetitive bits, then I understand why you’d be skeptical that AI will be transformational!

But this isn’t how real change works over time. Moving forward, AI’s capabilities will reshape workflows, roles, and org structures. But this kind of impact won’t arrive all at once, unfolding instead via a series of incremental steps which will only be obvious in hindsight. This is why we need to focus on that roadmap to envision what the future will really be like.

Fortunately, this is a common pattern which has happened multiple times in the past. In today’s post, I’m going to go back 150 years to look at one such technological transformation that also didn’t feel like a big deal in its early days: the electrification of factories. Walking through that 50-year history from about 1880 to 1930 highlights another instance where the initial implementation was met with a collective “meh”, and real value didn’t emerge until the workflows, roles, and org structures were reoriented around what that new technology made possible.

How factory electrification transformed production (in 5 phases, 50 years)

The story of how electrification transformed factories via second-order effects is a well-worn business school trope. What most people don’t realize a century later is (1) it didn’t happen all at once, (2) people thought it was overblown hype then too, and (3) it took a full 50 years from “hey check out this new tech!” until the full benefits were realized. (If this is interesting to you, Nicholas Carr wrote a 2008 book about it called “The Big Switch”. Great read!)

1. Before electricity: centralized mechanical power

Before electricity, factories ran on water or steam power. A large central engine turned a long rotating shaft that ran the length of the factory. Machines were physically connected to the shaft via belts, and their placement on the factory floor was dictated by their mechanical needs (similar torque, speed, and scheduling).

There was no flexibility. Machines were not arranged for workflow efficiency, they were just grouped by power compatibility. (Consultants of the era most likely circulated leaflets about machine “personas”—group your simple task machines in one line, high powered machines in another, etc.)

2. Early electrification: Woo-hoo! (Wait, how is this different?)

When electricity came onto the scene, the first wave of adoption was simple. Just swap out the central steam engines for electric motors. C’est simple!

I imagine vendor presentations at the “Future Factory Forum 1890” talking about how this is the “easiest onramp to electrification” because you can “re-use your existing infrastructure” and “be up and running in weeks instead of months!”

The challenge is that this steam engine-to-electric motor drop-in replacement didn’t provide a ton of new value. Sure, the electric motors might be more efficient, but they were also new and unfamiliar. Technicians and engineers were harder to come by (and probably more expensive)!

And of course, since all the individual machines were still driven by the large central shafts, they were locked into the same layout. New tech, old workflows. There was no real productivity gain.

3. Decentralized motors!

By 1900 or so, electric motors became reliable and affordable enough to attach directly to individual machines. This meant that the factories could remove the central drive shafts and all the belts. Huzzah!

While this was a huge technological advancement, factories kept the same layouts. Parts, people, workflows, shipping, receiving—everything in the factory was built around those machines being in that order and it wasn’t easy to change.

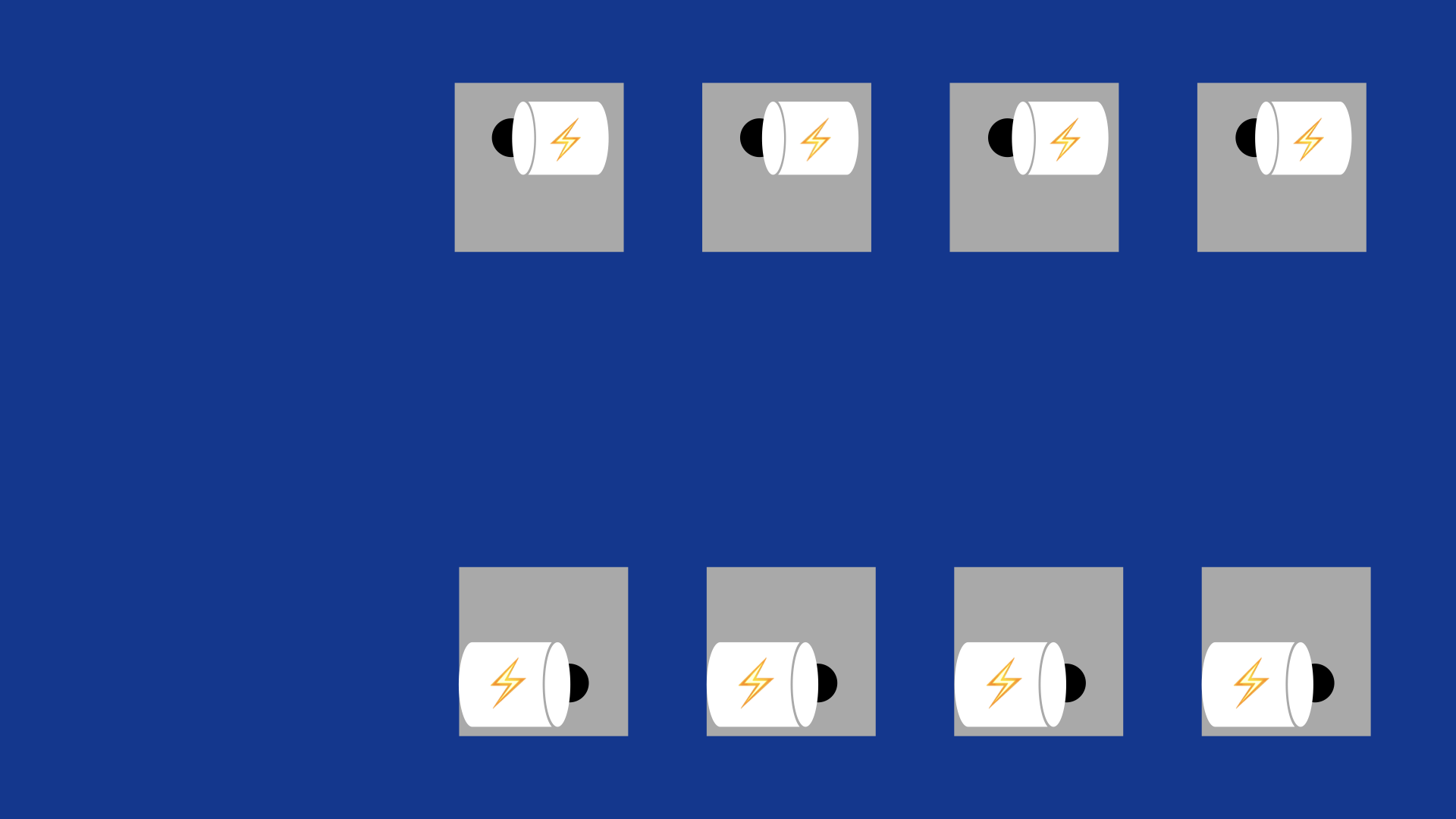

But zooming out looking at it was still pretty wild, as the machines and flows were arranged by the old constraints rather than the actual workflows:

4. The real transformation: eliminate old constraints, design for modernity

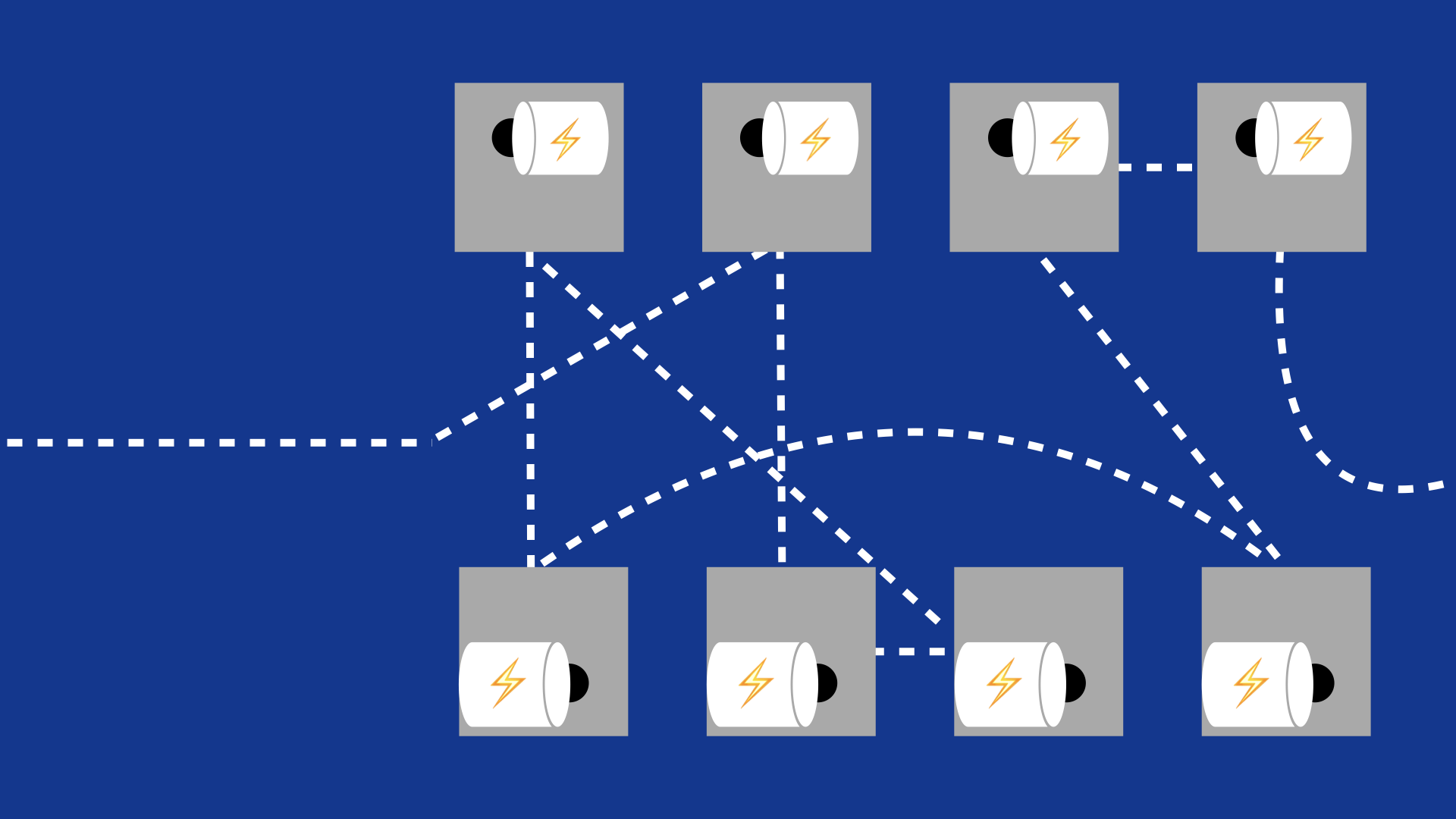

The real transformation came when someone realized, “Hey, now that these machines are truly independent from each other, we can move them.” They could be arranged by task order, not power requirements.

This was the birth of the modern assembly line. Machines, people, and processes were reorganized around flow, not antiquated hardware constraints. This is when productivity took off and the factory was truly transformed. Just took 50 years!

The new normal: a system built around the tech

Once factory managers began rethinking the layout of their machines, rather than just the technological change of how they were powered, everything changed and a major transformation happened.

What started as a seemingly small technical improvement ultimately led to entire new workflows, management practices, and organizational roles. It wasn’t just that the layout was different—the core logic of how a factory operates transformed.

This wasn’t because electricity made the machines run better—which it did—it was because electricity made it possible to rebuild the system around what the technology enabled. That’s the leap. And that’s what AI will do to the knowledge worker workspace in the coming years.

How this applies to AI in the workplace

Today, AI is being plugged into existing workflows built around the constraints of human workers. This is great! But it’s also just the beginning, similar to the first stage of swapping out the central factory engines with electric motors.

Over time, AI will start to reshape our existing workflows rather than just fitting into them. As its capabilities grow, (and as our understanding and comfort with it grows), AI will challenge assumptions (about when, where, and how work happens) that are so deeply embedded in the way we work today that we don’t even notice them. This is going to be huge and something that most people miss today.

Today’s workplaces are built around human constraints. Humans require rigid work / non-work cycles. We need meetings. We process information slowly. We have cognitive biases. We rely on memory, context, and coordination. We move data through screens and keyboards at a paltry 200 tokens per minute.

AI doesn’t have these limitations. It can run 24/7. It remembers everything. It can take in large volumes of structured and unstructured data at once and act on it without waiting for handoffs, emails, or status meetings.

This doesn’t just speed things up—it opens doors to entirely new ways of working. Just like factories were redesigned once electricity removed the physical constraints, AI will lead us to rethink how knowledge work is structured in a world without human bottlenecks.

Workflows will simplify. Roles will shift. Teams will be reorganized around outcomes instead of processes. These changes won’t all come at once, and they won’t always be obvious in advance. But step by step, the core organization of flows of knowledge work will shift, just like how electrification transformed factories.

Real transformation isn’t about installing new tools, it’s about outgrowing the assumptions those tools were originally designed to serve. It’s not about doing the same work faster; it’s about rethinking what work looks like in a world without the old constraints.

It happened a century ago with electricity. It happened more recently with the internet, smartphones, and cloud computing. And it will happen in the future as AI enters the workplace.

Read more & connect

Join the conversation and discuss this post on LinkedIn. You can find all my posts on my author page on the Citrix blog (or via RSS).

Video of my most recent talk

In May I gave the closing keynote at the EUCtech Denmark 2025 conference, called The Future of Work in an AI-Native World. I talked about a lot of what I covered today and walked through how AI will evolve and impact the workplace in the coming years. You can watch it on YouTube.

My upcoming talks

- AppManagEvent: Closing Keynote: AI & the Future of Enterprise Apps — Utrecht, Netherlands, Oct 10

- MAICON 2025: AI at Work: The Employees’ Revolution! — Cleveland, Ohio, Oct 14-16